Precision casting is at the forefront of the global foundry industry. Its greatest advantage lies in significantly reducing machining costs while enabling the production of complex components that cannot be machined through conventional methods. The application of precision casting technology is highly adaptable, evolving to meet diverse product requirements.

We specialize in lost wax casting for a variety of materials, including carbon steel and stainless steel. Our product range spans art statues, general hardware, industrial-grade components, as well as parts for the defense and aerospace industries.

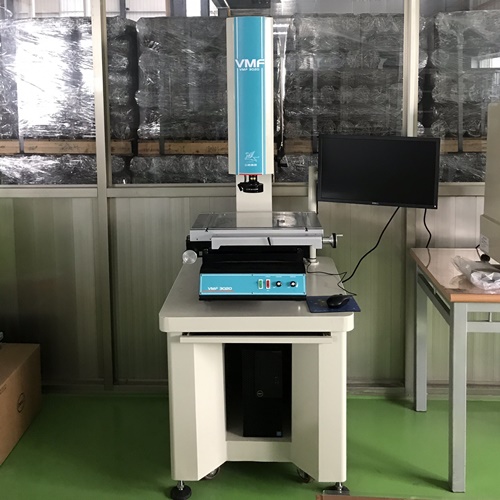

We specialize in precision machining of castings, delivering high-accuracy components tailored to our customers' exact specifications. Our capabilities cover a variety of materials, including carbon steel and stainless steel, ensuring superior dimensional precision and consistency.

Utilizing advanced CNC machining, milling, and turning technologies, we enhance the quality and functionality of cast components while minimizing material waste and production costs. Our stringent quality control processes guarantee that each part meets the highest industry standards, making us a trusted partner for industries requiring precision, reliability, and performance.

Let us help you achieve the perfect balance of precision and efficiency in your cast components.

We offer expert lost wax casting mold design and consulting services to help customers overcome challenges such as low yield rates caused by suboptimal molds. Our tailored solutions ensure improved casting precision, efficiency, and overall production quality.

In addition, we provide process improvement consulting for lost wax casting. By leveraging comprehensive data analysis and industry expertise, we assist customers in identifying and resolving manufacturing issues, optimizing production efficiency, and enhancing product yield. Our guidance helps accelerate development timelines and ensures a more stable, high-performance casting process.

Medical, Valve, Pneumatic tools, Special Steel Alloys, Construction, Aeroespacial, Industrial Machinery & Equipment, Maritime, Automotive

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

| Length and Weight | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

Tolerance Range |

||||||||||||||||||||||||

|

| Material | (C) | (Si) | (Mn) | (P) | (S) | (Cr) | (Mo) | (Ni) | (Nb) | (Cu) | (Other) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SUS304 | ≦0.08 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 18~20 | 8~11 | ||||

| SUS304L | ≦0.03 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 18~20 | 9~13 | ||||

| CF3M | ≦0.03 | ≦1.50 | ≦1.50 | ≦0.040 | ≦0.040 | 17~21 | 2~3 | 9~13 | |||

| CF3 | ≦0.03 | ≦1.00 | ≦1.50 | ≦0.035 | ≦0.020 | 17~20 | 8~12 | ||||

| SCS13 | ≦0.08 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 18~21 | 8~11 | ||||

| CF8 | ≦0.08 | ≦2.00 | ≦1.50 | ≦0.040 | ≦0.040 | 18~21 | 8~11 | ||||

| 316 | ≦0.08 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 16~18 | 10~14 | ||||

| CF8M | ≦0.08 | ≦2.00 | ≦1.50 | ≦0.040 | ≦0.040 | 18~21 | 2~3 | 9~12 | |||

| 1.4408 | ≦0.07 | ≦1.50 | ≦1.50 | ≦0.045 | ≦0.030 | 18~20 | 2~3 | 10~12 | |||

| SCS14 | ≦0.08 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 17~20 | 2~3 | 10~14 | |||

| 316L | ≦0.03 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 16~18 | 2~3 | 10~14 | |||

| SCS16 | ≦0.03 | ≦1.50 | ≦2.00 | ≦0.040 | ≦0.040 | 17~20 | 2~3 | 12~16 | |||

| 410 | ≦0.15 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 11.5~13.5 | |||||

| 420J1 | 0.16~0.25 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 12~14 | |||||

| 420J2 | 0.26~0.40 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 12~14 | |||||

| 431 | ≦0.20 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 15~17 | 1.25~2.5 | ||||

| 440A | 0.60~0.75 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.040 | 16~18 | ≦0.75 | ||||

| 440B | 0.75~0.95 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | 16~18 | ≦0.75 | ||||

| 440C | 0.95~1.20 | ≦0.10 | ≦1.00 | ≦0.040 | ≦0.030 | 16~18 | ≦0.75 | ||||

| 17~4/SCS24 | ≦0.07 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.040 | 15.5~17.5 | 3.00~5.00 | 0.15~0.45 | 2.50~4.00 | ||

| AISI310 | ≦0.25 | ≦1.50 | ≦2.00 | ≦0.045 | ≦0.030 | 24~26 | 19~22 | ||||

| SCH13 | 0.2~0.5 | ≦2.00 | ≦2.00 | ≦0.040 | ≦0.040 | 24~28 | 11~14 | ||||

| SUS347 | ≦0.08 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 17~19 | 9~13 | ≦10XC% | |||

| 4140 | 0.38~0.43 | 0.15~0.30 | 0.75~1.00 | ≦0.035 | ≦0.040 | 0.80~1.10 | 0.15~0.25 | ||||

| 8620 | 0.18~0.23 | 0.15~0.30 | 0.70~0.90 | ≦0.035 | ≦0.040 | 0.40~0.60 | 0.15~0.25 | 0.40~0.70 | |||

| 8640 | 0.38~0.43 | 0.15~0.30 | 0.75~1.00 | ≦0.035 | ≦0.040 | 0.40~0.60 | 0.15~0.25 | 0.40~0.70 | |||

| S15C | 0.13~0.18 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≦0.200 | ≦0.20 | ≦0.30 | |||

| S20C | 0.18~0.23 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≦0.20 | ≦0.20 | ≦0.30 | Ni+Cr≦0.35 | ||

| S25C | 0.22~0.28 | 0.15~0.35 | 0.30~0.60 | ≦0.030 | ≦0.035 | ≦0.20 | ≦0.20 | ≦0.30 | Ni+Cr≦0.35 | ||

| S30C | 0.27~0.33 | 0.15~0.35 | 0.60~0.90 | ≦0.030 | ≦0.035 | ≦0.20 | ≦0.20 | ≦0.30 | Ni+Cr≦0.35 | ||

| S45C | 0.42~0.48 | 0.15~0.35 | 0.60~0.90 | ≦0.030 | ≦0.035 | ≦0.20 | ≦0.20 | ≦0.30 | Ni+Cr≦0.35 | ||

| S50C | 0.47~0.53 | 0.15~0.35 | 0.60~0.90 | ≦0.030 | ≦0.030 | ≦0.20 | ≦0.20 | ≦0.30 | Ni+Cr≦0.35 | ||

| SK4 | 1.10~1.30 | ≦0.35 | ≦0.50 | ≦0.030 | ≦0.030 | ≦0.30 | |||||

| WCB | ≦0.030 | ≦0.60 | ≦1.00 | ≦0.040 | ≦0.045 | ≦0.50 | ≦0.2 | ≦0.5 | ≦0.30 | Cu+Ni+Cr+Mo+V≦1.00 | |

| SMN420 | 0.17~0.23 | 0.15~0.35 | 1.2~1.5 | ≦0.03 | ≦0.03 | ≦0.35 | ≦0.25 | ≦0.30 | |||

| CN7M | ≦0.07 | ≦1.50 | ≦1.50 | ≦0.040 | ≦0.040 | 19~22 | 2~3 | 27.5~30.5 | 3~4 | ||

| SCM415 SCM21 | 0.13~0.18 | 0.15~0.35 | 0.60~0.85 | ≦0.030 | ≦0.030 | 0.90~1.20 | 0.15~0.30 | ≦0.25 | ≦0.30 | ||

| SCM440 SCM4 | 0.38~0.43 | 0.15~0.35 | 0.60~0.85 | ≦0.030 | ≦0.030 | 0.90~1.20 | 0.15~0.30 | ≦0.25 | ≦0.30 | ||

| SNCM220 SNCH21 | 0.17~0.23 | 0.15~0.35 | 0.60~0.90 | ≦0.030 | ≦0.030 | 0.40~0.65 | 0.15~0.30 | 0.40~0.70 | ≦0.30 |

| JIS | AISI | DIN |

|---|---|---|

| Stainless Steel (Austenitic) | ||

| SUS304 | AISI 304 | DINx5CrNi1810 |

| SUS304L | AISI 304L | DINx2CrNi1911 |

| SUS310S | AISI 310S | |

| SUS316 | AISI 316 | DINx2CrNiMo17132 |

| SUS316L | AISI 316L | |

| SUS317 | AISI 317 | DINx2CrNiMo18164 |

| Stainless Steel (Martensite) | ||

| SUS410 | AISI 410 | DINx10Cr13 |

| SUS420JI | AISI 420 | DINx20Cr13 |

| SUS3431 | AISI 431 | DINx20CrNi172 |

| SUS440A | AISI 440A | |

| SUS440B | AISI 440B | |

| SUS440C | AISI 440C | |

| Stainless Steel (Ferritic) | ||

| SUS430 | AISI 430 | DINx6Cr17 |

| Cadmium Molbdenum Steel | ||

| SCM415 | ||

| SCM420 | ||

| SCM430 | 4130 | |

| SCM435 | 4135 | 34CrMo4 |

| SCM440 | 4140 | 42CrMo4 |

| SCM445 | 4145 | |

| High-Temperature Steel | ||

| SUH310 | AISI 310 | DINCrNi2520 |

| Carbon Steel | ||

| S10C | 1010 | C10 |

| S15C | 1015 | C15 |

| S20C | 1020 | C20 |

| S25C | 1025 | C25 |

| S30C | 1030 | C30 |

| S35C | 1035 | C35 |

| S40C | 1040 | C40 |

| S45C | 1045 | C45 |

| S50C | 1050 | C50 |

| S55C | 1055 | C55 |

| Carbon Tool Steel | ||

| SK3 | W1-10 | C105W1 |

| SK4 | W1-9 | |

| SK5 | W1-8 | C80W1 |

| High-Temperature Steel (Martensite) | ||

| SUH1 | ||

| SUH3 | ||

| SUH4 | ||

| SUH11 | ||

| Nickel Chrome-Molybdenum Steel | ||

| SNCM220 | 8620 | |

| SNCM240 | 8640 | |

| SNCM439 | 4340 | |

Precision lost wax casting overcomes the limitations of traditional sand casting by incorporating indirect modeling and advanced process control technologies. This allows for the production of highly precise, thinner, and more intricate castings while ensuring superior internal quality of the blanks.

CWIDE offers a diverse range of products, including art statues, general hardware, industrial-grade components, as well as parts for the defense and aerospace industries.

Key advantages of precision lost wax casting include a smooth, finely detailed surface, exceptional dimensional accuracy, and reduced material and machining costs. This method enables the creation of complex and lightweight structures with high mechanical strength, minimal porosity, and fewer shrinkage defects. Additionally, it supports diverse product designs, small-batch and high-mix production, and flexible manufacturing, ensuring consistent high quality and excellent manufacturability.

CWIDE has developed a unique engineering technology and management system through years of dedicated research in precision lost wax casting. By leveraging the distinct advantages of this process, we have optimized both production efficiency and product quality.

Our internal management system seamlessly integrates every stage of production, including sample development, testing, batch manufacturing, process control, quality management, tracking, data preservation, and document management. We also implement proactive exception handling and periodic system enhancements to continuously refine our operations.

Given the complexity of precision lost wax casting, transitioning from sample development to stable, high-quality production requires a highly intricate and interwoven process. Human expertise plays a crucial role in process yield, which is why CWIDE places strong emphasis on teamwork and a robust work ethic. To uphold our standards, we implement an annual education and training program to continuously enhance our team’s skills and knowledge.

Through the collective efforts of our employees and the continued support of our customers, CWIDE has established a strong competitive edge in highly industrialized markets worldwide.

-December,2011 Cwide Inc. was founded.

-August,2018 Headquarters office renovation.

-November,2023 Obtained ISO 9001:2015 certification.

-February,2025 Joined Taiwantrade.

People-Centered, Customer-Driven

Rigorous Standards, Uncompromising Quality

Innovation & Sustainability

Integrity & Truth

In a world of rapid change, precision and innovation are more crucial than ever. With a century-old heritage in craftsmanship and a dedicated team of ten, we deliver personalized service that upholds the highest standards.

To meet the demands of modern industry, we continuously refine our casting technology, embrace innovation, and harness the power of digital data to enhance accuracy and yield. By producing superior components, we strive to make a meaningful impact—shaping a better world, one casting at a time.